I’ve got a packed afternoon, but wanted to get this up for your weekend reading pleasures. It’s mostly me looking at some data and asking what the hell?

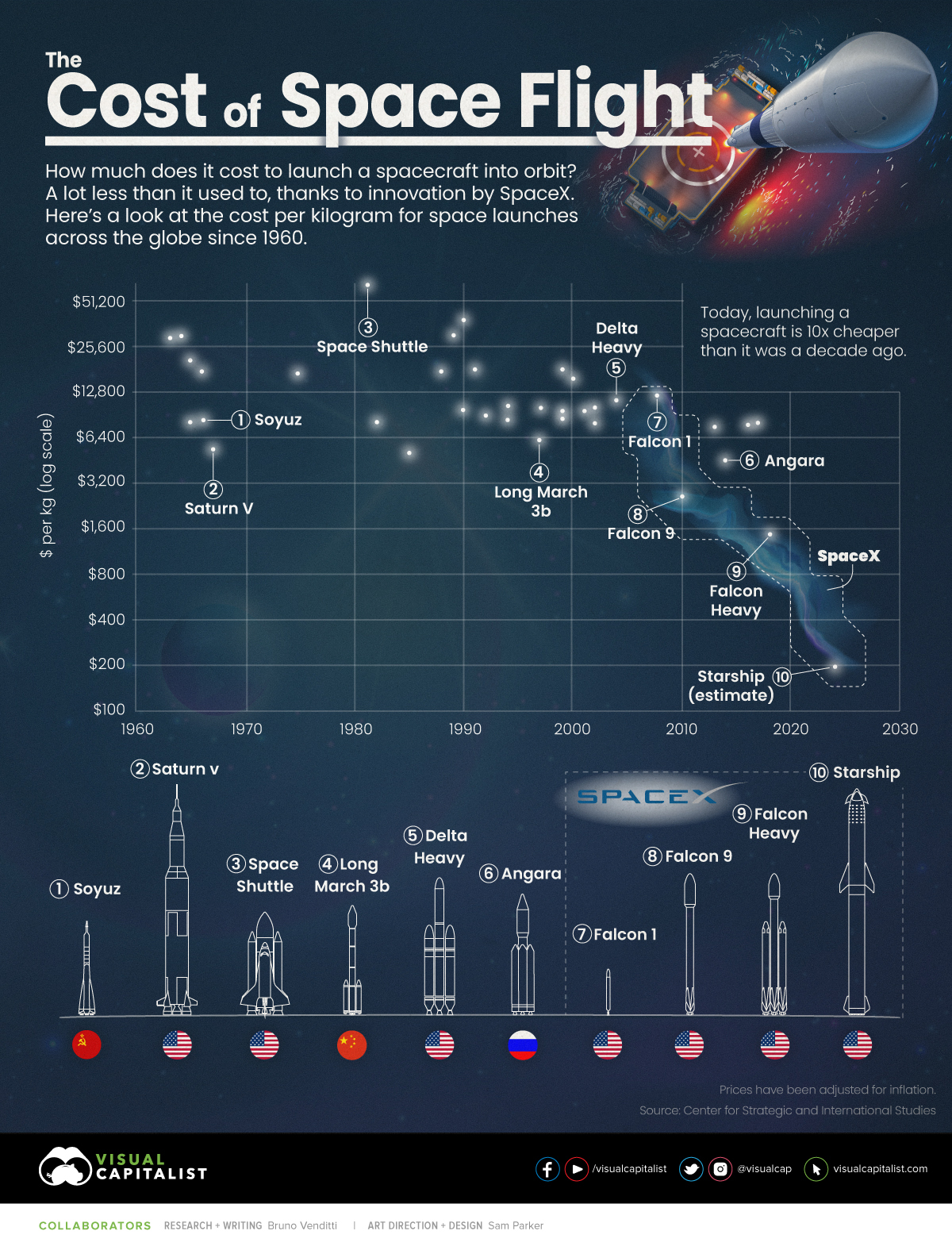

Came across this very interesting infographic while surfing the interwebz on the cost of space flight:

The key phrase for me was the “Today, launching a spacecraft is 10x cheaper than it was a decade ago.”

This fit in with what I’ve been mentioning off and on for years, how technology is getting cheaper and cheaper over time. Most recently, I talked about it in this post:

Efficiency reduces the cost of the inputs. Competition then results in lowering costs of the outputs — the product or service. Your dollars will buy more and more as time goes on, because technology keeps making things more efficient, which means cheaper.

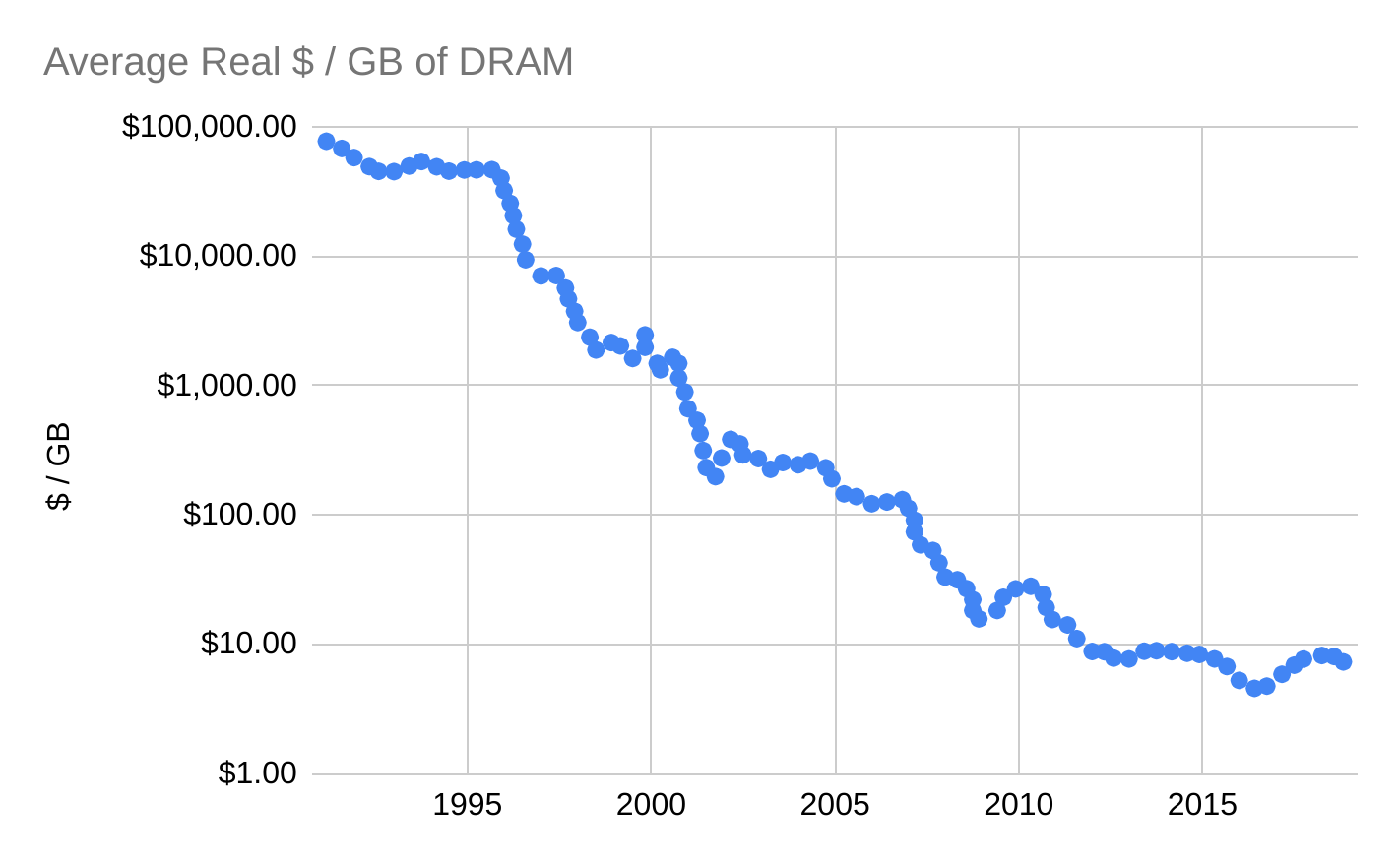

And we’re seeing this across our economic landscape. Look for example at the price of DRAM (computer memory):

But you already kind of knew this, because you see it and live with it every day.

Thanks to the inexorable and exponential march of technology, which makes things more and more efficient, production costs for everything from computer chips to clothing to food have fallen dramatically over the years. I remember my mom putting elbow patches on my sweater back in the late 70s; today, we have clothes that are cheaper to throw away than to dry clean.

So it got me wondering, given what is going on with home prices across the country, what about the cost of construction?

Cost of Construction

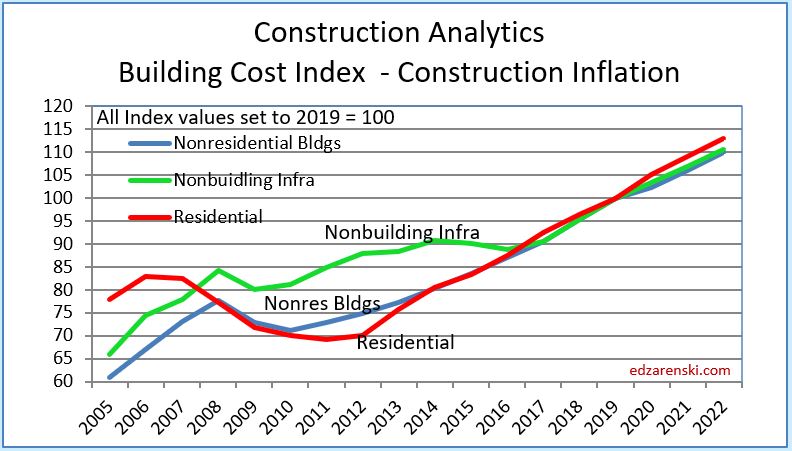

It is difficult for me to get my hands on really good historical data on cost of construction, especially in real dollar terms. If you’re in the construction side of things and have access to such data, please let me know. But I did find these charts from Construction Analytics by Ed Zarenski:

Again, this index is not adjusted for inflation (as far as I know), but it shows a straight up and to the right increase in construction costs for Residential buildings starting around 2012.

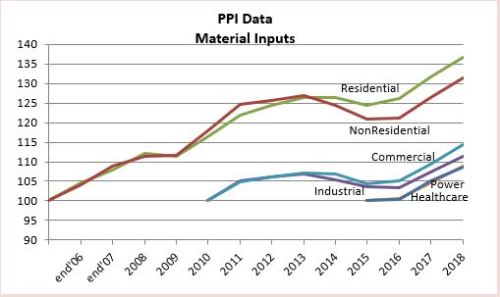

Certainly, part of the equation is the cost of materials. like lumber and concrete for the homebuilders. We certainly have heard a lot about supply chain disruptions and the like the last two years. Ed Zarenski provides this PPI chart:

Note that his data ends in 2018. And we’re seeing residential building materials going more or less straight and to the right, then dropping from mid-2012 to about 2016, then starting another price run up and to the right. Zarenski has some additional color:

- One year (2018) change

- biggest increases > Steel Pipe and Tube 21%, Fabricated Steel for Bridges 15%, Ornamental Metals 12%, Fab Structural Steel for Buildings 12%

- biggest declines > Copper and Brass shapes -6%, Lumber and Plywood -4%

- PPI Final cost of buildings and Trades up 4% to 6%

- Final cost of buildings posted largest increases since 2008.

- Final cost of trades (except for Roofing) posted largest increases since 2009.

- Steel Products posted largest increases since 2008

- Lumber and Plywood, which had risen dramatically (+30%) earlier in the year, now down 4% from Dec ’17

- Two year (2017+2018) changes

- biggest increases > Diesel fuel 45%, Steel Pipe &Tube 31%, Aluminum Shapes 16%, Fabricated Structural Metal for Buildings 16%, Ornamental metals 16%

- no declines over a two year period

I’m trying to wrap my head around this data.

Where’s Technology? Where’s Efficiency?

It doesn’t make a ton of sense to me that we have seen no improvements in efficiency in construction over the past 15 years or so. I assume that companies who service the construction industry have made investments into better and more efficient machinery and better technology. To use just one example, Caterpillar talks a whole lot about its innovation efforts:

The NAHB (National Association of Home Builders) has an annual Global Innovation Award. Presumably, they give that award out to companies that have developed some new technology, some new innovation, that drives efficiency, productivity, and so on.

All of that is deflationary. Technology is inherently deflationary. There just is no way on earth that a professional nail gun won’t save time over a worker using a hammer by hand.

Material prices have gone up since 2006 yes, but that would be the case for every industry, no? It isn’t as if SpaceX, which has driven the cost of spaceflight down 10x over ten years, doesn’t use steel or aluminum. It isn’t as if flatscreen TV’s don’t use materials; they do. So higher material costs are going to be the same for all industries.

Yet, they are driving the cost of production down, down, down… exponentially down.

Construction is not.

What’s up?

Two Hypotheses

Obviously, I don’t know why we haven’t seen the cost of construction come down over the years despite advances in technology. Again, I appeal to anyone with real construction experience to chime in with explanations.

But I do have two hypotheses on why we haven’t seen construction costs come down.

One, construction costs have come down in real terms, but inflationary money printing has more than eaten up the deflationary pressure from efficiency gains. If this is correct, then adjusting construction costs for inflation should show that the actual real costs of construction is 10x cheaper in 2022 than they were in 2012.

Somehow, I don’t think that’s the answer. Because inflation wasn’t that big a problem for 15 years; it’s only in the last two years that we’re seeing 6% and 7% CPI prints. Plus, inflation hits all industries, including technology, so that can’t be the sole reason.

Two, deflationary pressure from technology has been swamped by skilled labor shortage. Sure, the framer can do things 10 times faster with his framing nail gun than he can with a hammer, but his wages are up 12x, because there are fewer and fewer qualified framers. Ed Zarenski hints at this in this 2021 update post:

Contractors have been saying they have difficulty acquiring the skilled labor they need. This has led to increased labor cost to secure needed skills. I expect the decline in nonresidential work volume in 2021 to result in as much as a decline of 250,000 nonresidential jobs in 2021. This results in labor available to fill other positions.

With demand for housing having exploded over the years, and a shortage of skilled labor, the human costs outstrip any efficiency gains from technology.

Nonetheless, since other industries like auto manufacturing, spaceship building, or making microchips also require skilled labor… it isn’t clear to me why we haven’t seen any kind of decrease in cost of construction.

Perhaps the difference here is the uniqueness of construction versus any other kind of manufacturing: it must be done outside, and usually on-site. Auto manufacturing can use robotics to drive labor costs down, because making cars happens in a factory. Building a houses must be done on-site (for the most part), and as yet, we haven’t seen portable robotics and automation that can build houses at lower cost.

That is changing. Robotics and 3D printing are slowly penetrating into construction. But maybe we haven’t seen that impact cost yet.

Do You Know?

Let me end this by asking members of this community whether they know why the cost of construction hasn’t come down at all over the years, despite obvious advances in technology, which is inherently deflationary. Since the cost of production will obviously impact the cost of the final product (i.e., a home), this should be of singular interest to us in the real estate and housing industries.

-rsh

10 thoughts on “Why Haven’t Construction Costs Come Down?”

Look for the fingerprints of government. Space didn’t get cheaper until NASA lost their monopoly. Also, there aren’t stock options promising lottery size winnings anywhere in the construction industry for high powered brains. I bet there are some Twitter engineers that might be looking at other industries for a career with their stock options. Under water deeper than whale poop.

Thanks Tom. I imagine there have to be some kind of regulatory/government interference. I just can’t find any data on that either way. Maybe Ed Zarenski has some additional insights there. Trying to get him on a podcast to discuss this.

But on the stock option thing, I imagine there may be startups in the construction tech space who do offer lottery-size winning stock options. 🙂 If not, we have to ask why not.

Hey ROB,

I’m not a builder but am close to the construction business.

IMO, like so many industries it’s stuck in the past. Status quo.

While I figured we would have advanced by now progress is slow.

There was a time when it was possible to buy a house from a catalog. Contractors would take the materials out of a box and put the puzzle together in a week or two.

I believe, especially in the lower and middle tier price points we will head backwards to go forward.

Modular, prefabricated homes should become common. No lumber, prefabricated, high tech, efficient and inexpensive.

The trend will once again transform established and create new communities; affordable, sleek, modern with eco everything.

It’s available now. But we talking big time disruption and we know how tough it is to pull that off without upsetting the apple cart.

The cart doesn’t like to be upset.

#brave

We’ll see.

Thanks,

Brian

I watched 9/11 and the invasion of the mideast push a 4’x8′ sheet of OSB from 4.99 to over 20 bucks. It never came down close to that again. When disasters push the price of supplies up they rarely come down to their previous level. During the pandemic I paid over 60 bucks for that same sheet of plywood. Labor has always been a problem that still needs to be reckoned with. Our workforce in construction is woefully under educated and paid.

Interesting.

So do you think most of the cost increases are due to materials or to labor?

I am a Broker and small business owner of a millshop, supply company. Have been around construction since the 70’s and brokering since the late 90’s.

Some things never change. A house built today will have essentially the same materials of the 70’s, and techniques. They are predictable and consistent. Alternative materials exist, yes, but not in quantity, except PVC, engineered flooring, and Hardiplank.

The entire industry of res construction is based around wood. Trades, materials, tools, skills, all based around wood studs, subflooring, trim, flooring, and cabinets. Thats what people want. Cherry wood paneling, crown molding, entry doord that make you go wow!

I see it this way. Some things never change. You will always need the human hand to cut hair, you will always enter a home through a door, your home will always have a toilet, shower, sleeping quarters, kitchen. Aside from modular (not mobile) construction, which is a far superior product but is limiting, is there really a need to change? As i sit here in my kitchen, looking at my cabimets, crown, table…does it really need to change? Do i want it to change?

The NAHB did studies in the late 90’s of builing homes (single family detached) with steel studs. It worked great, resistent to termites, fire, etc. But, roof trusses were wood. Roofing wood and shingles unchanged. Although it makes perfect sense, didnt catch on. Of course with steel now essentially produced outside US, probably never will, and best it didn’t.

In my millshop it is nearly impossible to find a true craftsman, finish carpenter, or cabinet maker. However, i do see young guys coming in wanting to learn, but expect to be paid what a journeyman tradesman is paid for OJT. Unfortunately i have to pay him premium and jack up my tradesman to keep them, causings cost to go through the roof!

Got a call from 2 attorneys who want cabinets, only cabinet company that called them back, and my shop has a 5 month lead. All other local shops are telling folks its 4 months just to look at plans. I am in the southeast, and am shipping cabinets to New York.

1.5 years ago i was buying poplar at 90 cents to 1.25 per board foot. Now it is 3.15 a board foot with fuel surcharges on delivery. Cabinet grade plywood 86 bucks a sheet, vs 42 last year.

So my real estate brokerage is selling homes at 75k over asking, avg sales price is up 30%, payroll for my millshop is up 30%, and my raw materials are up over 100%. All of this in the last 18 months. Not to mention my cabinet hardware is sitting on some container ship 6 miles offshore 50th in line to unload…

Lastly, what is causing this? People with money are bailing out of the urban centers where armed robbery is now a misdemeanor. Who wants to live there? They come to a mid sized city, buy a relative castle for 500k, work from home and commute to Wall street once evry 2 weeks. The local buyers get crowded out of the market, and the feeding frenzy snaps up homes in 24 hours. Builders are trying to build but the quotes i gave them last month on flooring, trim, and cabinets have doubled due to all of the above, their appliances are sitting on a ship, and they cant build for the sales price.

Its everything. Cheap money. Labor. Materials. Shipping. Pent up demand. Everything.

Whew! Don’t get me started!

This is so, so good. Thank you Tom.

Have you thought about converting the normal articles into audio? I take the text into Amazon Polly in order to convert text into audio so I can listen while driving around. I know I can see the graphs when I do this but a great way to get the content along with the podcasts. I was going to paste the link here but the URL definitely looks like a Russian hacker site. I’ll email if you want.

I have. In fact, I’m looking for a way to make that a VIP feature. 🙂 Wonder how many other people would want the “audio version” of my posts.

Worth giving it a shot – maybe try it on the public side to gauge engagement then move to VIP if it makes sense and maybe help convert people to VIP from standard

Comments are closed.